1. Introduction: Dismantling the June 1976 Myth

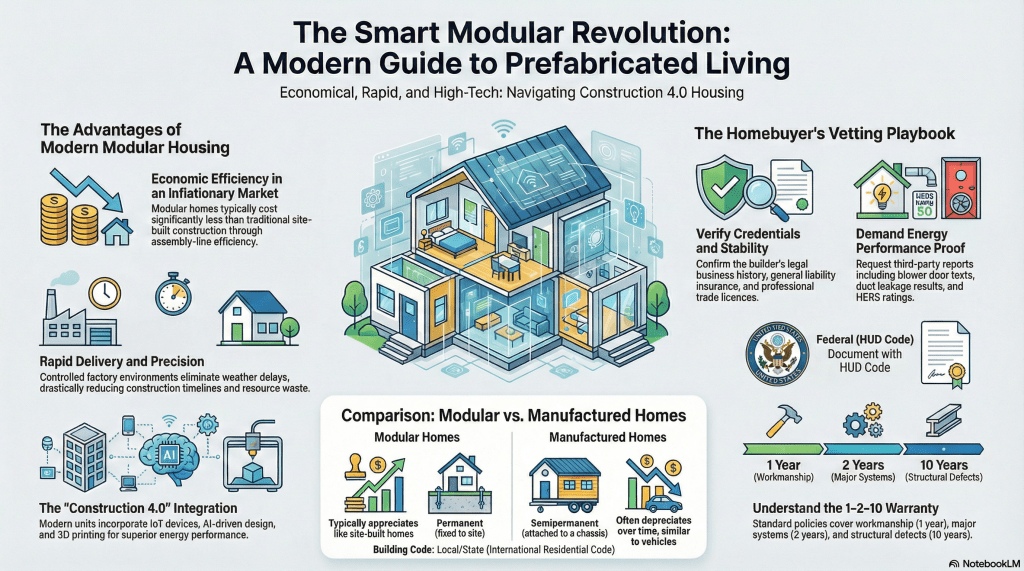

In the 2025 economy, the term “mobile home” is not just a social stereotype; it is a technical anachronism. As an innovation analyst, I frequently remind stakeholders that, legally, a “mobile home” refers only to factory-built units constructed before June 15, 1976. Since that date, the industry has bifurcated into HUD-regulated manufactured housing and high-performance modular architecture.

Today, as traditional site-built construction faces crippling “sticker shock”—driven by a 2025 inflation cycle, labor shortages, and material volatility—a high-tech revolution is quietly occurring. We are moving away from the “trailer park” stigma toward digitally-driven, climate-neutral dwellings. The following analysis distills why the shift from reactive site management to predictive factory manufacturing is the only viable path forward for the modern real estate market.

2. Takeaway 1: Your Future Home Has a “Digital Twin” (The Predictive Shift)

The hallmark of “Construction 4.0” is the transition from static blueprints to dynamic Digital Twins. In traditional builds, site management is notoriously reactive; errors in framing or HVAC routing are often discovered weeks too late, leading to cascading costs. Modular construction pivots this to a predictive model.

By utilizing IoT devices, RFID tags, and BIM (Building Information Modelling), builders monitor a module’s “Calibration Twin” from the factory assembly line to on-site stitching. This allows us to validate environmental performance—such as indoor temperatures and energy loads—against digital simulations before the keys are even handed over.

“New technologies are reshaping the construction industry, further extending its horizon towards the concept of Construction 4.0, where industrial production… and digital technologies… enhance the productivity and efficiency of a sector known for its traditional methods and slow adoption of technological advancements and innovations.” — Modular Construction in the Digital Age: A Systematic Review

While we are currently in the “Calibration Twin” phase, the data suggests a rapid pivot toward full-scale automated twins that will eventually govern autonomous robotic assembly.

3. Takeaway 2: The “1/3 Cost” Factor and the Mortgage Gatekeeper

The financial divergence between modular and manufactured housing is the most critical factor for middle-class wealth accumulation in 2025. While a manufactured home costs approximately one-third as much as a site-built home, the financing structure determines its long-term ROI.

| Feature | Manufactured Home | Modular Home |

| Governing Code | Federal HUD Code (Post-1976) | Local State / International Residential Code |

| Foundation | Affixed to a permanent metal chassis | Permanent foundation (site-built style) |

| Financing | Often Chattel loans (higher rates) | Traditional Mortgages |

| Asset Class | Titled as Personal Property (initially) | Titled as Real Property |

| Resale Profile | May depreciate (like an automobile) | Appreciates with local real estate market |

Analysis: The “Chattel loan” vs. “Traditional Mortgage” distinction is a significant financial gatekeeper. Modular homes, by adhering to the same local codes as site-built houses, allow owners to tap into traditional financing and equity growth, whereas manufactured homes on leased land may lose value over time, despite their lower entry cost.

4. Takeaway 3: Carbon-Negative Living through Non-Destructive Disassembly

The modular revolution is fundamentally a materials revolution. By adopting a “Cradle to Cradle” philosophy, we are moving away from “destructive demolition” toward a “Kit of Parts” approach. Because modular units rely on precise mechanical connections, they can be dismounted at the end of their lifecycle, allowing materials to be harvested rather than landfilled.

- Negative Carbon Insulation: Cork, a renewable Mediterranean resource, remains the only insulation with a negative carbon footprint.

- Recycled PET Fibers: We are seeing polyester fibers from recycled bottles converted into “thermal wadding” for high-performance wall cavities.

- Vernacular 3D-Printing: Using 3D-printed compressed earth blocks offers a low-cost, thermally efficient alternative to carbon-heavy cement, especially in arid climates.

- Agricultural Byproducts: Straw is being utilized as a high-performance thermal insulator, turning cereal cultivation waste into a carbon-sequestering building component.

5. Takeaway 4: The Houston Playbook—Vetting as a Technical Sport

In high-stakes climates like Houston, vetting a builder requires more than a background check; it requires an audit of their building physics. As an architectural technologist, I look for a “Systems Approach” that accounts for extreme humidity and flood risk.

The Technologist’s Red Flag Checklist:

- Oversized/Undersized HVAC: Refusal to provide Manual J (load calculations), Manual D (duct design), and Manual S (equipment selection) reports.

- Missing Energy Metrics: Absence of a HERS (Home Energy Rating System) report or a SEER rating appropriate for the Southern climate.

- Testing Refusals: Refusal of third-party Blower Door or Duct Leakage testing to verify the building envelope’s integrity.

- Warranty Structure: A “builder-administered” warranty is a risk. Demand a 1-2-10 structure (1 year workmanship, 2 years systems, 10 years structural) backed by a third-party insurer to ensure protection even if the builder ceases operations.

6. Takeaway 5: The “Off-Grid” Holy Grail and the Care Node

We are witnessing the rise of the nZEB (nearly-Zero Energy Building). These modular units generate their own power through integrated photovoltaics and geothermal systems, but the true innovation lies in how this energy independence facilitates the “Care Crisis.”

In 2025, a resilient home is a “Care Node.” By achieving nZEB energy independence, the home ensures that life-saving sensors—such as AI-driven fall detection and chronic disease monitoring for seniors—remain operational even during grid failures. The smart home is no longer about “convenience”; it is a proactive healthcare environment that bridges the gap between shelter and medical stability.

7. Conclusion: A New Architectural Renaissance

The 2025 economy has rendered the slow, wasteful methods of traditional construction obsolete. We are entering an era where precision-manufactured, sustainable housing is the benchmark, not the exception. By leveraging Digital Twins, circular “Cradle to Cradle” materiality, and rigorous technical vetting, modular housing offers a faster, safer, and leaner path to ownership.

Final Thought: As we redefine the residential landscape, we must ask: Does a community’s sense of “belonging” still depend on traditional bricks and mortar, or is it now rooted in the digital intelligence and material circularity that allow a home to be both a high-performance asset and a responsible neighbor to the planet?

For homeowners, investors, and developers exploring modern construction methods, understanding prefab before committing capital is critical. I’ve put together a Premium U.S.–focused guide that breaks down how prefab structures actually work, how they compare to traditional builds in cost and timelines, and what buyers need to know about codes, safety, and real-world results. If you’re considering a construction decision in 2025 or beyond, this guide will help you evaluate prefab with clarity and confidence. You can access it here: https://payhip.com/b/x10WQ

Leave a comment